(photo credit: Garden of Praise)

(photo credit: Garden of Praise)Michael Barone lays this out very carefully in this linked article - as only someone who grew up in Detroit can offer. Yet he also has his political background pushing through as he nutshell's Obama's success and how Detroit could emulate it in their necessary reorganization:

RealClearPolitics - Articles - Detroit Automakers a Relic of the Past: "Obama's presidential campaign was an entrepreneurial enterprise whose success owed much to harnessing individual initiative through an innovative management structure and creatively using emerging technology. The campaign, as well as the candidate, helped inspire under-30 voters, who preferred Obama by an unprecedented 66 percent to 32 percent margin -- as opposed to his 50 percent to 49 percent margin in those 30 and over.I am reminded of some new kids on the block, which are borrowing a very old "Just In Time" manufacturing process for autos. A German article points out that the Europeans are well ahead in this area:

But keeping the Detroit Three in their present form, with their extravagant health care benefits and the union's 5,000 pages of work rules, is an exercise in preserving in amber the America of the past."

Logistics. This is fast becoming one of the most innovative parts of the industry. Saving money by reducing the number of suppliers with a ‘just-in-time’ manufacturing system means that parts are supplied on demand and transported very quickly (within a matter of days) from where they’re made to where they need to be used. Therefore, very little is kept in stock and space is optimised. Europe’s logistics infrastructure is already advanced.

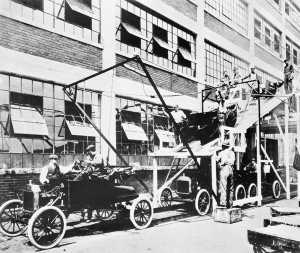

And here is yet another example, showing that Americans were probably the first to create the model of efficient auto manufacturing:

Benjamin Franklin, possibly the United States’ first well-known efficiency expert, said in his 1758 The Way to Wealth, “You call them goods; but, if you do not take care, they will prove evils... if you have no occasion for them, they must be dear to you. Remember what Poor Richard says, ‘Buy what thou hast no need of, and ere long thou shalt sell thy necessaries.’” Whether or not Franklin could have envisioned twenty-first century automotive manufacturing processes and inventories is doubtful, but nevertheless, his folksy words still deliver industrial-strength wisdom 250 years after he wrote them.

Lean manufacturing has no doubt existed in some form since the earliest of enterprises, but for the auto industry it was Henry Ford who first examined squandered time, effort, materials, and ideas, citing Franklin as one of his inspirations. Again and again in the decades that followed, Ford and Franklin proved themselves correct as vastly larger enterprises adopted their ways of thinking. After World War II, the U.S. War Department exported lean principles to the devastated nations of Europe and Asia. In Japan, the principles were enthusiastically adopted, and the kaizen culture of industry quickly took hold. The word kaizen means “improvement,” or, more specifically, “to take apart and put back together in a better way.” It became one of the methods used by Taiichi Ohno as a daily practice of manufacturing philosophy at Toyota. Today, U.S. manufacturers have Americanized the word kaizen and combined it with blitz to mean an intensely focused short-term project of efficiency improvement. Franklin’s thoughts have come back home.

Probably, they should take their model from Dell computers:

But no one has gone as far as Dell. It's well known, of course, for nearly eliminating finished-goods inventory by cutting out resellers and connecting directly to customers. What's less known is how it has transformed the back end of its operations -- its assembly lines and supply chain -- into one of the fastest, most hyperefficient organizations on the planet. Eleven years ago, Dell carried 20 to 25 days of inventory in a sprawling network of warehouses. Today, it has no warehouses. And though it assembles nearly 80,000 computers every 24 hours, it carries no more than two hours of inventory in its factories and a maximum of just 72 hours across its entire operation. Dell's vast, global supply chain is in constant overdrive. Says Hunter: "Speed is at the core of everything we do."This article continues to how Dell finances it's manufacturing line:

The implications of working in this kind of hyperdrive -- in Dell time -- are profound. It changes the finance model, and it's an enormous competitive weapon. On average, computer makers pay their suppliers 30 days before a PC is shipped to market, bought by a customer, and paid for. But Dell's build-to-order model lets it receive payment from its customers immediately -- through credit cards, either online or over the phone. It pulls the parts directly from its suppliers and builds and ships the product within four days. Yet the company doesn't pay those suppliers until 36 days after it receives payment from the customer. So Dell has achieved a cash-conversion cycle (that's the time between an outlay of cash for parts and the collection of payment for goods made from them) of negative 36 days. That means it operates with negative working capital, eliminating the need to finance its operations. "By collecting money for products from customers before it owes money to its suppliers, Dell has made it so its suppliers finance the cost of Dell's operations," says Tom Mentzer, executive director of the integrated-value chain forums at the University of Tennessee at Knoxville.

A couple of years ago, I found a company who was making auto's strictly on demand, with its parts (like Dell above) owned by the supplier until it was actually installed on the vehicle. Unfortunately, I've not today been able to find even the name of that vehicle, although it has started to be imported into the US this year - with a three-lunged diesel engine as one offering.

Their plant had four suppliers building their own plants in adjoining four corners of the assembly line. That line then went through each supplier and the parts were installed in sequence. No car was built until it was specified and bought. Delivery time was within weeks.

The below article examines (briefly) how such a model might impact our current automotive manufacturing process:

By now, you may be thinking that I’m not serious. T-shirts, coffee and teddy bears? But apply this concept to how cars are made and sold today. A company decides what a car should look like—what color it is, what adornments it has—and sends it out the door to be sold (or not) based on market research. Now imagine an on-demand model where a customer comes to an automotive design and assembly center where they can personalize their car any way they want and have it assembled from inventory and emerging manufacturing processes.

But you first have to go simplistic - much as Henry Ford did with the Model T and A. You start with what people need and then go for what they want.

What do you really need in a vehicle? Mostly, room for a couple of people to commute to work and home. Some might need a larger vehicle that holds four in order to take the kids to their variously scheduled appointments (soccer, ballet, music lessons, etc.). So we probably have two cars per family.

How fast do you really need to go? Most city limits (except for freeways) are 35 mph. 50 mph would keep you relatively safe on freeways as a top speed (and there will be arguments about this - but let me continue, please.)

If you designed a car which could be built on demand with readily replaceable parts, one which was configured to get best fuel economy/mileage at 35 and could read 50 if you needed - then you get into the realm where a 40-50 mile round trip is feasible for an electric vehicle. A hybrid approach would be to put a diesel (can run on vegetable oils) in line, such that it could be started up if the batteries got low - and would be charging the batteries while it was running - if need be.

The parts and technology for this are already present. Part of this research for this post revealed that go-kart manufacturers have simple 4-speed with reverse transmissions. Go-karts operate in the range we specified above (while their modeling and luxuries leave something for the average consumer).

Kohler manufactures small diesels, as well as gas engines. You just have to determine how much of an engine you have to have to tote around about 1000 lbs. of car and another 1000 lbs. of riders with their gear (less for commuters, more for families with kids).

Figure that a small diesel engine geared down to a small transmission and capable of running in town at lower speeds - well, you've just solved the majority of automotive need in this country. Now, let people design their own cars (a process I've heard advertised for the last several years) and you could add on all sorts of wants. (And those wants add both value and profit to the manufacturer's process.)

An electric car, batteries and all, would be able to handle commuter needs with just an overnight charge. A small diesel backup would take care of emergencies.

And the whole thing could be manufactured in hours, delivered in days.

As well, your plants don't need to be centrally located due to history. Locate them in easy shipping distance to save these costs. One in Nevada, one near St. Louis, one in Virginia (or South Carolina) - your plants are below the worst freeze zones and shipping is easier to anywhere in the US.

There's your Detroit bailout - complete restructuring from the ground up.

- - - -

OK - so I've said it. Anyone have any take on this?

No comments:

Post a Comment